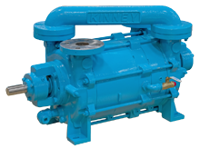

Kinney Tuthill Water Ring Vacuum Pumps – Proven Technology for Industrial Applications

Kinney Tuthill liquid ring vacuum pumps are robust and reliable industrial pumps with proven technology. These water ring vacuum pumps deliver excellent performance in demanding industrial applications and are characterized by their durable construction.

💧 Main Features:

- ✓ Single-stage or two-stage liquid ring vacuum pumps

- ✓ Robust cast iron construction – for decades of service

- ✓ Proven Kinney Tuthill technology – over 135 years of experience

- ✓ High reliability and long service life

- ✓ Simple maintenance and servicing

- ✓ Suitable for continuous industrial operation – 24/7

- ✓ Various seal configurations available

📊 Technical Specifications:

| Type | Ultimate Pressure | Pumping Speed |

|---|

| Single-Stage Pumps |

up to 100 mbar |

30 - 1,500 m³/h |

| Two-Stage Pumps |

up to 33 mbar |

30 - 1,500 m³/h |

- ✓ Suitable for various operating liquids

- ✓ Wide operating temperature range

- ✓ Air-cooled or water-cooled versions

🔧 Pump Series:

📦 KSC Series – Single-Stage Standard Pumps

| Parameter | Value |

|---|

| Type: |

Single-stage liquid ring pump |

| Ultimate Vacuum: |

up to 100 mbar (abs) |

| Application: |

Standard industrial applications |

✅ Benefits of KSC Series:

- ✓ Cost-effective single-stage design

- ✓ Robust construction

- ✓ Easy maintenance

- ✓ Suitable for medium vacuum applications

- ✓ Various sizes available

🔄 KTC Series – Two-Stage High Vacuum Pumps

| Parameter | Value |

|---|

| Type: |

Two-stage liquid ring pump |

| Ultimate Vacuum: |

up to 33 mbar (abs) |

| Application: |

Deeper vacuum requirements |

✅ Benefits of KTC Series:

- ✓ Deeper ultimate vacuum through two-stage design

- ✓ Higher efficiency at low pressures

- ✓ Energy-optimized operation

- ✓ Ideal for demanding processes

💪 KLRC Series – Pumps for High Pumping Speeds

| Parameter | Value |

|---|

| Type: |

Large capacity liquid ring pumps |

| Pumping Speed: |

up to 1,500 m³/h |

| Application: |

Large-scale industrial processes |

✅ Benefits of KLRC Series:

- ✓ Very high pumping speeds

- ✓ For large process volumes

- ✓ Extremely robust design

- ✓ Designed for heavy-duty operation

🏭 KTCL Series – Two-Stage Pumps with Large Delivery Volume

| Parameter | Value |

|---|

| Type: |

Two-stage high-capacity pumps |

| Ultimate Vacuum: |

up to 33 mbar (abs) |

| Pumping Speed: |

up to 1,500 m³/h |

✅ Benefits of KTCL Series:

- ✓ Combination of high capacity and deep vacuum

- ✓ Optimized for large-scale processes

- ✓ Maximum efficiency

- ✓ For most demanding applications

Available Kinney Tuthill liquid ring pump models: KSC-21, KSC-32, KSC-43, KSC-54, KSC-65, KSC-76, KSC-87, KTC-21, KTC-32, KTC-43, KTC-54, KTC-65, KTC-76, KLRC-150, KLRC-200, KLRC-300, KLRC-400, KTCL-150, KTCL-200, KTCL-300, KTCL-400, single-stage liquid ring pumps, two-stage liquid ring pumps, water ring pumps, industrial vacuum pumps, high capacity pumps, cast iron pumps, continuous duty pumps

💧 Liquid Ring Technology – Operating Principle:

⚙️ How It Works:

- Eccentric impeller rotates in a cylindrical housing

- Operating liquid (usually water) is thrown to the housing wall by centrifugal force

- A liquid ring forms on the inner wall

- Crescent-shaped working chambers cyclically enlarge and reduce in volume

- Gas is drawn in through the inlet port when chambers enlarge

- Gas is compressed when chambers reduce

- Compressed gas is discharged through the outlet port

✅ Advantages of Liquid Ring Technology:

| 💪 Extremely Robust |

No metal-to-metal contact – virtually wear-free operation |

| 💨 Wet Compression |

Can handle moist gases, vapors, and condensates without problems |

| 🌡️ Isothermal Process |

Operating liquid continuously cools and seals the pump |

| 🧹 Self-Cleaning |

Operating liquid washes contaminants out of the pump |

| 🔧 Low Maintenance |

Few moving parts, minimal wear |

| 🔥 Explosion-Safe |

No spark generation, suitable for flammable gases |

| 🛡️ Tolerant |

Can handle dust, particles, and contaminated gases |

| ♻️ Environmentally Friendly |

Water as operating medium – no oil contamination |

🏭 Ideal Applications:

Kinney Tuthill liquid ring vacuum pumps are perfectly suited for:

| Industry | Applications |

|---|

| 🧪 Chemical Industry |

Vacuum distillation, evaporation, crystallization, solvent recovery, reactor venting |

| 🏭 Process Industry |

Drying processes, degassing, concentration, filtration |

| 📄 Paper Manufacturing |

Paper machine dewatering, vacuum rolls, pulp deaeration |

| 🥫 Food Industry |

Vacuum packaging, food preservation, freeze drying, sugar processing |

| 🏗️ Plastics Processing |

Thermoforming, extrusion, degassing, vacuum forming |

| ⚗️ Distillation |

Vacuum distillation columns, fractional distillation |

| 💨 Evaporation |

Multi-effect evaporators, concentrators |

| 🌊 Degassing |

Water treatment, oil degassing, steel degassing |

| 🔥 Drying |

Vacuum dryers, tray dryers, rotary dryers |

| 🔌 Impregnation |

Transformer impregnation, motor winding impregnation |

| 🧪 Filtration |

Vacuum filters, belt filters, drum filters |

🔩 Design Features:

- ✓ Cast iron housing – extremely durable and corrosion-resistant

- ✓ Bronze or stainless steel impeller – depending on application

- ✓ Mechanical face seals – reliable sealing

- ✓ Spheroidal graphite iron shafts – high strength

- ✓ Various seal materials – for different media

- ✓> Modular construction – easy component replacement

- ✓ Multiple connection options – flexible installation

- ✓ Air or water cooling – depending on operating conditions

💧 Operating Liquids:

| Operating Liquid | Advantages | Applications |

|---|

| 💧 Water (Standard) |

Cost-effective, readily available, environmentally friendly, good cooling effect |

Most standard applications |

| 🛢️ Oil |

For deeper vacuum, higher operating temperatures, better sealing at low pressures |

Deep vacuum applications |

| 🧊 Glycol Solutions |

Freeze protection for outdoor installation, operation below 0°C possible |

Cold climate applications |

| 🧪 Special Liquids |

Chemically resistant liquids for aggressive media, solvents |

Chemical industry, special processes |

🔧 Our Service for Kinney Tuthill Liquid Ring Pumps:

| 🛒 Sales |

New pumps from all series – KSC, KTC, KLRC, KTCL |

| ♻️ Complete Overhaul |

Full reconditioning with replacement of all wear parts |

| ⚙️ Repair |

Seal replacement, impeller repair, bearing replacement |

| 📦 Spare Parts |

Original parts in stock: seals, impellers, bearings, shafts |

| 🚗 On-Site Service |

Installation, commissioning, maintenance at your location |

| 🔍 Diagnostics |

Performance testing and condition assessment |

| 💡 Consultation |

Application engineering and system optimization |

📊 Single-Stage vs. Two-Stage – Which is Right?

✅ Choose Single-Stage (KSC Series) When:

- Ultimate vacuum of 100 mbar is sufficient

- Cost-effective solution desired

- Simple design preferred

- Standard industrial applications

- Rough vacuum sufficient

✅ Choose Two-Stage (KTC/KTCL Series) When:

- Deeper vacuum (down to 33 mbar) required

- Higher efficiency at low pressures needed

- Energy optimization important

- Demanding process requirements

- Better performance in critical vacuum range

⚙️ Maintenance & Service Life:

🔧 Typical Maintenance Intervals:

| Maintenance Task | Interval |

|---|

| Operating liquid check |

Daily |

| Operating liquid replacement |

Every 3-6 months |

| Seal inspection |

Every 6-12 months |

| Bearing inspection |

Every 12-24 months |

| Complete overhaul |

Every 3-5 years |

💪 Service Life:

With proper maintenance, Kinney Tuthill liquid ring pumps can operate for 20-30 years or more. The robust cast iron construction and wear-resistant design ensure maximum reliability.

🌟 Why Choose Kinney Tuthill Liquid Ring Pumps?

| 🇺🇸 American Quality |

Proven technology since 1886 – over 135 years of experience |

| 💪 Legendary Robustness |

Cast iron construction for decades of service |

| 🌊 Wet Process Specialist |

Ideal for humid and contaminated applications |

| 🔧 Simple Maintenance |

Easy servicing, long maintenance intervals |

| 🔥 Explosion-Safe |

Suitable for flammable and explosive atmospheres |

| 💰 Economical |

Low operating and maintenance costs |

| 🌍 Proven Worldwide |

Tens of thousands in operation globally |

Need a Kinney Tuthill Liquid Ring Vacuum Pump?

Whether single-stage KSC series for standard applications, two-stage KTC series for deeper vacuum, or high-capacity KLRC/KTCL series for large-scale processes – our Kinney Tuthill experts are happy to advise you in selecting the optimal liquid ring vacuum pump for your specific industrial requirements.

We also offer professional service and complete overhaul for your existing Kinney Tuthill liquid ring pumps. With original spare parts and decades of experience, we restore your pump to peak performance.

American industrial quality since 1886 – professional local service! Contact us today for expert consultation and proven liquid ring vacuum technology.