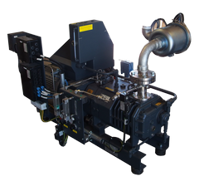

Busch COBRA Dry Screw Vacuum Pumps - Models NC 0040, NC 0100, NC 0200, NC 0400, NC 0600, NC 0900 - Ultimate Vacuum to 0.05 mbar

Busch COBRA screw vacuum pumps represent the pinnacle of dry-running vacuum technology, engineered specifically for demanding industrial applications requiring deep vacuum levels and absolute oil-free operation. These high-performance pumps utilize precision-engineered screw rotors that operate without contact, eliminating the need for operating fluids while achieving ultimate pressures down to 0.05 mbar.

The revolutionary screw compressor principle adapted for vacuum generation makes COBRA pumps uniquely suited for processes involving aggressive chemicals, condensable vapors, and contaminated gases where traditional oil-sealed pumps would fail. With ATEX certification available and exceptional chemical resistance, COBRA systems set the industry standard for reliability in hazardous and demanding environments.

Technical Performance Specifications:

- Ultimate Vacuum: Down to 0.05 mbar (0.0375 Torr) - true deep vacuum capability

- Pumping Speed Range: 40 m³/h to 720 m³/h (24 CFM to 424 CFM)

- Motor Power: 1.5 kW to 45 kW (2 HP to 60 HP) depending on model

- Operating Principle: Dry-running twin screw rotors with no internal contact

- Cooling System: Air or water-cooled versions available

- Seal Technology: Advanced mechanical seals or magnetic drive options

- Materials: Corrosion-resistant coatings and special alloys for aggressive media

Complete COBRA Model Range:

All available models: NC 0040 A/B, NC 0100 A/B, NC 0200 A/B, NC 0400 A/B, NC 0600 A/B, NC 0900 A/B

- NC 0040 A/B: Compact entry model, 40 m³/h, 1.5-2.2 kW, ideal for laboratory and pilot plant applications

- NC 0100 A/B: Small industrial model, 100 m³/h, 4-5.5 kW, versatile for diverse processes

- NC 0200 A/B: Medium capacity, 200 m³/h, 7.5-11 kW, standard industrial workhorse

- NC 0400 A/B: High throughput, 400 m³/h, 15-18.5 kW, for demanding production environments

- NC 0600 A/B: Heavy-duty industrial, 600 m³/h, 22-30 kW, continuous operation capability

- NC 0900 A/B: Maximum capacity flagship, 720 m³/h, 37-45 kW, for large-scale industrial installations

- Variant Designations: "A" suffix = air-cooled, "B" suffix = water-cooled configuration

Dry Screw Technology Revolutionary Advantages:

- Absolutely oil-free operation eliminates product contamination risk

- No operating fluids means zero disposal costs and environmental compliance

- Handles condensable vapors and aggressive chemicals without degradation

- Non-contact screw rotor design ensures minimal wear and extended service life

- Consistent pumping speed across entire pressure range from atmosphere to deep vacuum

- High compression ratios enable single-stage deep vacuum generation

- Low vibration operation suitable for sensitive environments

- Integrated gas ballast for vapor handling capacity

- Frequency inverter compatibility for variable speed energy optimization

- Compact footprint with vertical or horizontal mounting options

ATEX Explosion Protection:

COBRA pumps are available with full ATEX certification for deployment in potentially explosive atmospheres. These specially configured models incorporate explosion-proof motors, intrinsically safe electrical systems, and constructional measures preventing ignition sources - essential for chemical processing, solvent handling, and pharmaceutical manufacturing where flammable vapors may be present.

Primary Industrial Applications:

Chemical & Petrochemical Processing: Distillation columns under vacuum, solvent recovery systems, reactor vessel evacuation, polymer degassing, crystallization processes, monomer recovery, vapor phase reactions, specialty chemical synthesis requiring contamination-free vacuum

Pharmaceutical & Fine Chemicals: Active pharmaceutical ingredient (API) drying and crystallization, freeze drying (lyophilization) systems, vacuum distillation of heat-sensitive compounds, sterile filtration, tablet coating chambers, clean room vacuum applications, solvent removal from drug formulations

Packaging & Film Coating Industry: Metallization vacuum chambers for aluminum coating, plasma treatment systems, sputtering processes, vacuum web coating, flexible packaging film production, barrier coating applications, optical film manufacturing

Plastics Processing & Extrusion: Polymer devolatilization, extrusion degassing, vacuum calibration of profiles, thermoforming molds requiring deep vacuum, plastic compounding volatile removal, sheet extrusion vacuum sizing

Vacuum Drying Technologies: Pharmaceutical drying chambers, chemical intermediate drying, heat-sensitive material processing, vacuum tray dryers, rotary vacuum dryers, belt dryers under vacuum, solvent removal systems

Food & Beverage Processing: Freeze concentration, vacuum evaporation, aroma recovery, edible oil deodorization, sugar refining under vacuum, flavor extraction, critical food processing requiring oil-free vacuum

Environmental & Analytical: Mass spectrometry sample preparation, environmental testing chambers, accelerated aging tests, vacuum impregnation, resin infusion processes, composite manufacturing

Special Features & Configurations:

- Chemical Resistance Packages: Special coatings and materials for highly corrosive gases (HCl, HBr, chlorine, etc.)

- Hot Gas Versions: Inlet temperatures up to 180°C for superheated vapor handling

- Inert Gas Purge Systems: Nitrogen or argon purging for oxygen-sensitive processes

- Integrated Condensers: Upstream vapor condensation reducing pump load

- Multi-Stage Configurations: Series connection for ultra-deep vacuum below 0.01 mbar

- Process Control Integration: PLC connectivity, SCADA compatibility, Industry 4.0 readiness

- Acoustic Enclosures: Sound-dampened housings reducing noise emissions below 70 dB(A)

Energy Efficiency & Operating Economics:

- Variable frequency drive (VFD) control matches pump speed to process demand

- Intelligent vacuum control systems prevent over-pumping waste

- High compression efficiency reduces energy consumption per volume pumped

- No consumable operating fluids eliminates ongoing material costs

- Extended maintenance intervals with no oil changes required

- Predictive maintenance monitoring reduces unplanned downtime

- Heat recovery options capture waste heat for process integration

Maintenance & Service Advantages:

- Minimal Maintenance Requirements: Service intervals up to 8,000-12,000 operating hours

- Modular Design: Quick-change components minimize downtime during servicing

- Remote Diagnostics: Web-based monitoring enables preventive intervention

- Bearing Technology: Long-life precision bearings with advanced lubrication

- Mechanical Seal Life: Extended seal life exceeding 20,000 hours in standard applications

- Simplified Overhaul: Factory-trained technicians perform complete pump rebuilds

Comprehensive Service Portfolio in Austria:

We provide complete turnkey COBRA screw vacuum pump solutions including professional consultation and system design engineering, sales of all COBRA models with full technical support, genuine Busch original spare parts with immediate availability, on-site commissioning and startup assistance, preventive maintenance contracts tailored to your operation, emergency repair services with rapid response times, complete pump overhaul and refurbishment services, performance testing and optimization diagnostics, ATEX certification documentation support, operator training programs for safe and efficient operation, rental pump availability for temporary requirements, and 24/7 technical support hotline.

System Integration & Accessories:

- Vacuum controllers and pressure sensors for automated operation

- Inlet particle filters protecting pump internals from contamination

- Exhaust condensers and separators for vapor recovery

- Silencers and mufflers for noise reduction

- Safety relief valves and vacuum breakers

- Heat exchangers for temperature management

- Interconnecting pipework and flanged connections

- Vibration isolation mounts for sensitive installations

- Emergency shutdown and safety interlock systems

Quality & Compliance:

- ISO 9001 certified manufacturing ensuring consistent quality

- CE marking for European market compliance

- ATEX certification for explosive atmosphere applications

- FDA-compliant materials for pharmaceutical and food applications

- ASME and PED pressure equipment directives

- Energy efficiency compliance with EcoDesign directives

Why Choose COBRA Screw Vacuum Pumps:

When your process demands the ultimate in vacuum performance without compromise on cleanliness, chemical resistance, or reliability, BUSCH COBRA screw vacuum pumps deliver unmatched capabilities. The oil-free operation eliminates product contamination concerns critical in pharmaceutical and food applications, while the robust screw technology handles the most aggressive chemicals without degradation. With ultimate vacuum capability to 0.05 mbar and pumping speeds up to 720 m³/h, COBRA pumps provide the performance headroom needed for demanding industrial processes. ATEX-certified models ensure safe operation in hazardous environments, and our comprehensive service network in Austria guarantees maximum uptime for your critical vacuum applications.