Busch SAMOS Side Channel Blowers for Vacuum and Pressure - Models SB 0021, SB 0040, SB 0063, SB 0100, SB 0140, SI 0160, SI 0260, SI 0330, SI 0500, SI 0680, SI 1200

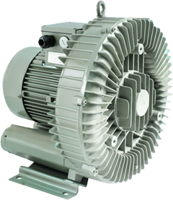

Busch SAMOS side channel blowers represent proven regenerative technology designed specifically for continuous operation in wastewater treatment facilities, industrial production environments, and environmental applications requiring moderate vacuum or low-pressure compressed air delivery.

The distinctive side channel design utilizes laminar flow principles to achieve exceptional volumetric efficiency while maintaining compact dimensions. Unlike traditional vacuum pumps, SAMOS blowers operate completely oil-free with minimal internal friction, resulting in extended service intervals and outstanding reliability in harsh operating conditions.

Technical Specifications Overview:

- Single-Stage Models (SB/SI Series): Flow capacity 40–2200 m³/h, Vacuum up to 360 mbar, Pressure up to 460 mbar

- Two-Stage Models (SB/SI Series): Flow capacity 80–1200 m³/h, Vacuum up to 445 mbar, Pressure up to 500 mbar

- Power Range: 0.2 kW to 22 kW (0.27 HP to 29.5 HP)

- Maximum Air Flow: Up to 1400 m³/h (824 CFM) depending on configuration

- Frequency: 50/60 Hz models available for worldwide deployment

- Protection Class: IP54/IP55 suitable for outdoor installations

Complete Model Range:

- SB Series (Compact Single-Stage): SB 0021 D, SB 0040 D, SB 0063 D, SB 0100 D, SB 0140 D

- SI Series (Industrial Single-Stage): SI 0160 D, SI 0260 D, SI 0330 D, SI 0500 D, SI 0680 D, SI 1200 D

- Two-Stage Versions: Available across both SB and SI series with enhanced pressure differential

- Special Configurations: ATEX-certified explosion-proof versions, sound-dampened variants, process-specific customizations

Regenerative Side Channel Technology Benefits:

- Oil-free and maintenance-minimal operation – no lubrication required

- Continuous duty cycle capability for 24/7 operation

- Self-cooling aluminum die-cast housing with integrated cooling fins

- Pulsation-free air delivery for sensitive process requirements

- Low noise emissions with optional acoustic enclosures available

- Robust construction resistant to dust, moisture, and temperature fluctuations

- Variable speed control compatible for energy optimization

- Compact footprint minimizing installation space requirements

- Reverse-flow protected impeller design preventing foreign object damage

Primary Application Sectors:

Wastewater & Environmental: Municipal and industrial sewage treatment plant aeration, activated sludge diffusion systems, grease trap ventilation, odor control exhaust systems, biogas circulation and methane handling

Aquaculture & Agriculture: Fish farm oxygenation, shrimp pond aeration, hydroponic nutrient solution circulation, grain drying and conveying, silo ventilation systems

Industrial Manufacturing: Pneumatic component actuation, material conveying through pipelines, vacuum lifting and holding systems, packaging machinery vacuum generation, plastic welding exhaust extraction, printing press paper handling

Food & Beverage: Bottle cleaning air knives, product drying systems, vacuum packaging lines, pneumatic ingredient transfer

Operational Advantages:

- Energy Efficiency: Optimized impeller geometry reduces power consumption versus traditional blowers

- Reliability: Precision-balanced rotors ensure vibration-free operation and extended bearing life

- Versatility: Single unit can function as vacuum pump, pressure blower, or combination unit

- Environmental Compliance: Zero oil contamination risk meets strict environmental regulations

- Cost Effectiveness: Minimal spare parts requirements and simple maintenance procedures

Comprehensive Service Portfolio:

We provide complete turnkey solutions including SAMOS blower sales for all models, professional service and repair for all blower brands regardless of manufacturer, genuine Busch original spare parts inventory, acoustic silencers and sound attenuation housings, pressure relief and control valves, on-site field service at customer facilities, emergency rental blower fleet for temporary requirements, exchange repair program minimizing downtime, preventive maintenance contracts, performance testing and diagnostic equipment, and technical consultation for system optimization.

Customization Options:

- Integrated frequency inverters for flow modulation

- Stainless steel construction for corrosive environments

- Thermal overload protection and automatic restart functionality

- Remote monitoring capabilities with Industry 4.0 connectivity

- Multi-blower manifold configurations for redundancy